Item Sync |

This option allows the Ultriva Item master data to be in synch with the ERP Item master data. The fields marked as Required Yes are mandatory fields. Required fields must always have non-empty data.

If an item already exists in the Ultriva master, this process updates the item During the update process one could pass -1 for NUMBER fields and empty string for string fields for not updating the field value. |

To reset a string field value you may pass $$reset |

An item file may contain same item number multiple times if an item is supplied by multiple vendors. |

Ultriva Item Sync manages following:

Item Properties:

Updates an existing Item if the given Item Number is found in the Business Unit context

If given item is not found then process Creates a new Item in the given business unit context

Item to Supplier Relationship Properties:

If Item2Supplier details are given then the process also updates the Item2Supplier properties. (For instance a file may contain suppliercode and leadtime details then Ultriva Item sync updates or adds the Item2Supplier relationship data. Please note that for an existing item this process does not create new supplier relationship.)

Loopsize Management:

The process also creates loopsize (Kanban Cards creation or adjusting the existing loopsize) if the setting is enabled for Loopsize setup.

The following table defines the fields in Item Data file. The fields marked as bold are required. Required fields must always have non-empty data.

Item Master Data File (inbound to Ultriva)

Field Name | Data Type | Length | Required | Nullable | Description | Destination Table |

|---|---|---|---|---|---|---|

ItemNo | STRING | 32 | Y | N | This must be unique part number with in given Business Unit Code | Item |

ItemDesc | STRING | 255 | Y | N | Item Description | Item |

PlantCode | STRING | 32 | Y | N | Plant Code. A single file may contain data for a business unit and it's workcenters. | Item |

PlantUserCode | STRING | 32 | Y | N | Buyer or Item co-ordinator user Code. This field may contain Ultriva user name here or User's buyer code field value. | Item |

UsagePerDay | NUMBER | N/A | Y | N | It is the average daily demand or average usage per day for the Part Number. This value is used in the Kanban Card Calculation. | Item |

SafetyTime | NUMBER | N/A | Y | N | Represents the Safety Stock you wish to carry for that part. For e.g. for a 2 day safety stock you enter a value of 2. | Item |

QtyOnCard | NUMBER | N/A | Y | N | It is the standard lot size used by the supplier for replenishment (box or palette or container size). This is used as the Quantity per Kanban Card | Item |

VendorCode | STRING | 32 | Y | N | Supplier Business Unit Code. If given supplier business unit code is not found then this record will be errored out | Item2Supplier |

LeadTime | NUMBER | N/A | Y | N | Lead Time in Business Days | Item2Supplier |

TransitTime | NUMBER | N/A | Y | N | Transit Time in Business Days | Item2Supplier |

HandlingTime | NUMBER | N/A | Y | N | Handling Time in Business Days | Item |

PricePerUOM | NUMBER | N/A | Y | N | Unit Price of this item | Item |

BeginOnHandQty | NUMBER | N/A | Y | N | Begin On Hand Units. System will create cards in the on-hand state. During the 1st time this field is mandatory | Item |

CurrentOrderQty | NUMBER | N/A | Y | N | Current Order Units. System will create cards in the InProcess state. 1st time mandatory | Item |

ReorderPoint | STRING | 32 | N | Y | One of the following: OpenBox, EmptyBox. Default is OpenBox | Item |

ItemCategory | STRING | 32 | N | Y | One of the following values: Kanban, Virtual, Forecast. Default is Kanban | Item |

UOM | STRING | 64 | N | Y | UnitDescription - This filed is Unit of Measure. For Eg Ea-(Each), Pcs(Pieces). | Item |

SupplierItemNo | STRING | 64 | N | Y | Supplier Item Code. This is an optional field. If not given Plant Item No is used. | Item2Supplier |

SupplierItemDesc | STRING | 255 | N | Y | Supplier Item Description. This is an optional field. If not given plant Item description is used. | Item2Supplier |

FamilyCode | STRING | 64 | N | Y | Optional Product Line code. If not given then Unknown is assumed. | Item |

ClassificationCode | STRING | 64 | N | Y | Opitonal Commodity Code. If not given then Unknown is assumed. | Item |

MinOrderQty | INTEGER | N/A | N | Y | Minimum Number of orders. Used for Runline | Item2Supplier |

SupplierPoNum | STRING | 32 | N | Y | Blanket Supplier PO Number if any | Item2Supplier |

SupplierPoLineNum | INTEGER | N/A | N | Y | Blanket Supplier PO Line Number if any | Item2Supplier |

SupplierUserCode | STRING | 32 | N | Y | Supplier Coordinator User Code | This field may contain Ultriva username here |

LocationCode | STRING | 32 | N | Y | Item Location code if any | Item |

Integration_HasPOReceipt | INTEGER | N/A | N | Y | This flag tells if we need integration point. 1 or 0 | Item |

Integration_HasPORelease | INTEGER | N/A | N | Y | This flag tells if we need integration point. 1 or 0. 1 means the card will wait for PO after consumption | Item |

IsConsignment | INTEGER | N/A | N | Y | Is this item Vendor Managed Item? 1 or 0. | Item |

InspectionRequired | INTEGER | N/A | N | Y | Is this item needs inspection after Receipt? 1 or 0. 1 means Inspection Required | Item |

Additional Flex Fields in Item Master File (inbound to Ultriva)

Additional to the fields mentioned above ERP could send some advanced fields in the Flex field format. The Field name should start with EBJ_RTPARAMS and then a dot then a field name. For e.g. EBJ_RTPARAMS.RevisionNo would set the Revision Number in the item master.

| Please note that the Flat file's field names can be mapped to Ultriva Field names through configuration. For e.g. an incoming file may contain a field called Drawing_Number and this field can be mapped to Ultriva field name EBJ_RTPARAMS.DrawingNo. |

Field Name | Data Type | Length | Required | Nullable | Description | Destination Table |

|---|---|---|---|---|---|---|

EBJ_RTPARAMS.DrawingNo | STRING | 32 | N | Y | Drawing Number for this item | Item |

EBJ_RTPARAMS.SUBINVENTORY | STRING | 32 | N | Y | Subinventory for this item | Item |

EBJ_RTPARAMS.RevisionNo | STRING | 32 | N | Y | Revision Number for this item | Item |

EBJ_RTPARAMS.SW | STRING | 32 | N | Y | Shipping Weight for this item | Item |

EBJ_RTPARAMS.ABCCode | STRING | 32 | N | Y | ABCCode for this item | Item |

EBJ_RTPARAMS.CT | STRING | 32 | N | Y | Container Type of this item | Item |

EBJ_RTPARAMS.SUP_ALLOCATION | NUMBER | N | Y | Supplier Allocation Percentage | Item2Supplier | |

EBJ_RTPARAMS.CarrierCode | STRING | 32 | N | Y | Default Carrier Code | Item2Supplier |

EBJ_RTPARAMS.PO_TYPE | STRING | 8 | N | Y | Purchase Order Type BLANKET, QUOTATION, IR_ISO, INTER_ORG | Item2Supplier |

EBJ_RTPARAMS.PO_QTY | NUMBER | N | Y | If PO_TYPE is Blanket then this value is used to set | Item2Supplier | |

EBJ_RTPARAMS.PUR_USER | STRING | 32 | N | Y | If this is a valid Login Name in Ultriva then Item’s Purchase Coordinator value will be resolved to this user GID | Item |

EBJ_RTPARAMS.IsPutaway | NUMBER | N/A | N | Y | If putaway has to be enabled then pass 1 otherwise 0. | Item |

EBJ_RTPARAMS.toloc.ctrl | NUMBER | N/A | N | Y | This is used for inter-org shipment. If the destination location is locator controlled then pass 1 otherwise 0. | Item |

EBJ_RTPARAMS.ApprvRL | NUMBER | N/A | N | Y | This is used for enabling Runline Approval flag. If Runline Approval has to be enabled then pass 1 otherwise 0. | Item2Supplier |

EBJ_RTPARAMS.I2Sfrmloc.ctrl | NUMBER | N/A | N | Y | This is used for inter-org shipment. If the source location is locator controlled then pass 1 otherwise 0. | Item2Supplier |

EBJ_RTPARAMS.I2SFrom.loc | STRING | 32 | N | Y | This is used for inter-org shipment. Pass the location code. | Item2Supplier |

Processing Logic

An Import Process imports the file. During the import if it finds missing values or wrong data then it marks those records as errors. Remaining records are imported into Batch Table for further processing.

After successful importing of the data, a batch job processes each set of item records.

The process checks if the given item number exists for given plant code. If it is not found then it will create an item. If it is found then it will update that item record

The process checks if the given vendor code is already associated to the business unit if not it checks the parent business unit for supplier association, if the association is found then it creates a new association to this business unit.

If given product line or commodity code does not exist then the process creates those master entries.

Item Sync Process can be configured to run the Kanban Loopsize setting too, There are four options allowed:

Full Resize during only initial item creation

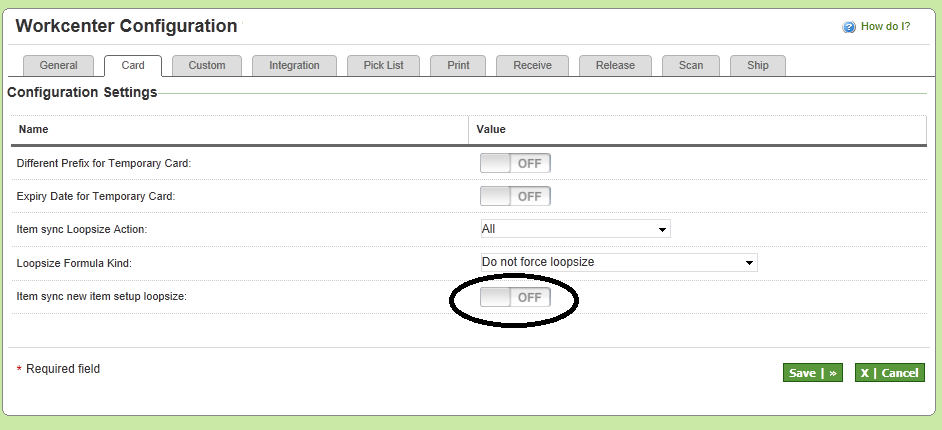

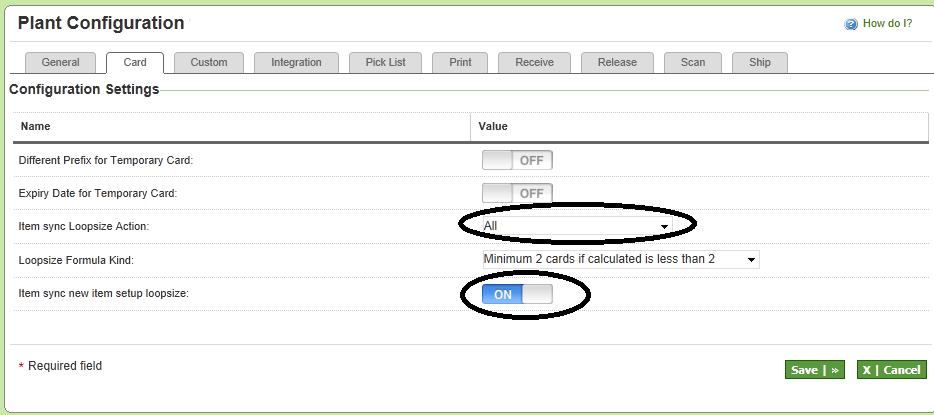

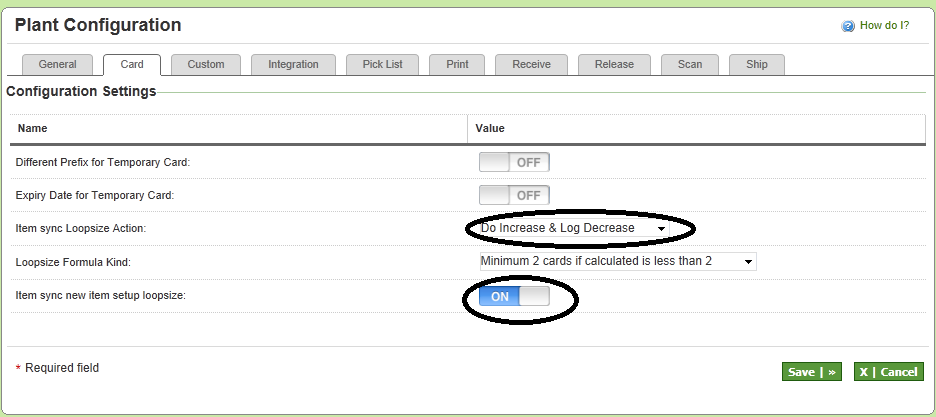

Here is how to enable or disable this setting through Application GUI. This setting is under business unit configuration.

Full Resize during initial and update of an item

Here is how to enable or disable this setting through Application GUI. This setting is under business unit configuration.

Full Resize and Resize only if cards to be added during update

Here is how to enable or disable this setting through Application GUI. This setting is under business unit configuration.

No Resize

Care must be taken if the item sync is configured for Full Resize |

Item Sync Processor may mark incoming records with specific error messages during interface processing.

The following table shows the error messages and their meaning:

In the following table the placeholders are encoded with curly braces. |

Error Message | Meaning |

|---|---|

Given UserCode <{0}> is not found in the system or not associated to BusUnit <{1}> | Job Processor unable to locate the given user in the input data. It uses one of the following ways to resolve the given user to users in the Ultriva user master.

|

Given User Object is disabled. UserCode <{0}> BusUnit <{1}> | Ultriva is able to locate the user. However the given user is disabled in Ultriva. |

Invalid Item Category | Given Item Category must be one of the following

|

Given Reorder Point is not valid | Given Reorder point must be one of the following

Given Reorder point may also by NULL. In that case Ultriva treats it as Open Box. |

Trying to create a New Item. One or more of SupplierCode not associated to Plant <{0}>. NoOfRows expected {1} - Found {2} | Given Supplier Code is not associated to the given Business Unit Code. |

Loopsize Creation failed. Calculated Loopsize {0} exceeds max {1} cards check | Loopsize adjustment is enabled. Calculated Number of cards to be created is exceeding number of cards that are allowed to created in a single attempt setting in the business unit. |

Invalid Value for Lead Time and Transit Time. At least one of the fields should have a valid value | Both Lead Time and Transit Time are less than 0. |

Given supplier code not found. Unable to get record for this filter | Job Processor is unable to resolve the Supplier Code. |

This is an update operation and ItemGID should not be empty | During Update operation the processor is not able to locate the item gid (primary key in Ultriva item master). |

Negative value for Supplier Allocation is not allowed | Supplier Allocation Percentage is less than 0. |

New Item. Invalid SafetyStock <{0}> | This item is a new item and hence the SafetyStock value must be given and should be greater than 0. |

New Item. Invalid QtyOnCard <{0}> | This item is a new item and hence the QtyOnCard value must be given and should be greater than 0. |

UpdateKanbanItem does not support new supplier association (No Supplier Allocation Percent is given). Please create the association manually for this supplier <{0}> and Item <{1}> | The given item already exists in Ultriva. This is an update operation. However input data contains a new supplier to be associated. To associate a new supplier for existing item, Supplier_Allocation % must be given. |

Unable to resize the Loopsize because previously read DelCardsCnt did not match with the value in the system | There is a del cards count value has been setup for this item. However some other transaction has updated the value. |